Plant planning

Essential for a successful implementation of a project is the planning

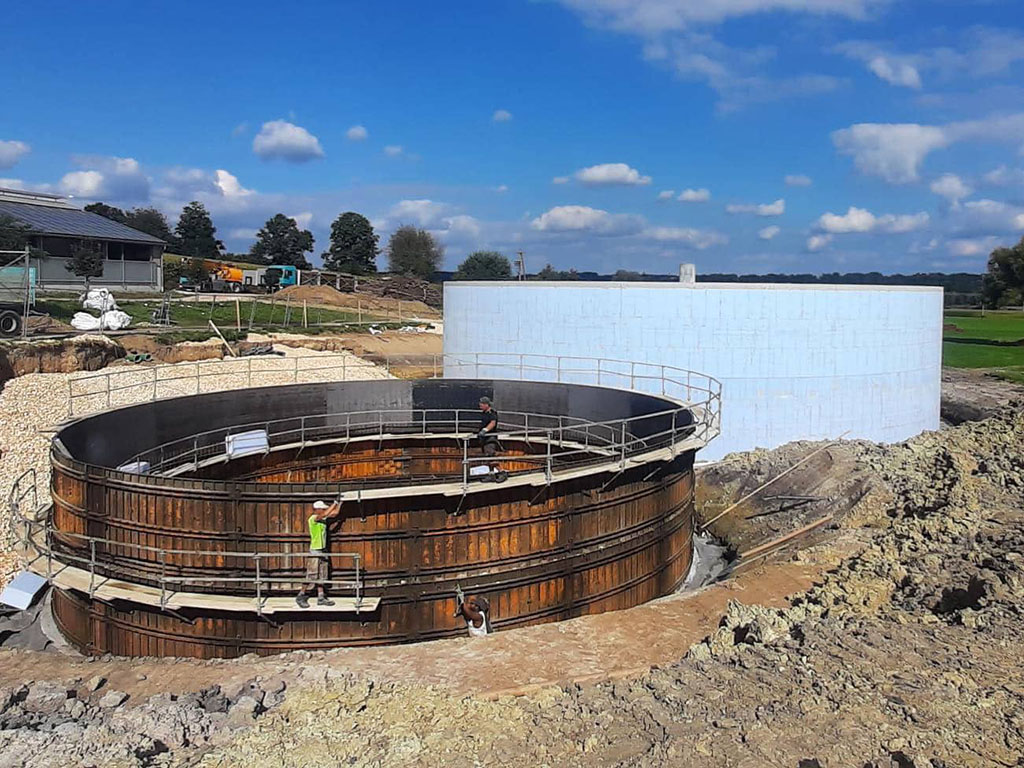

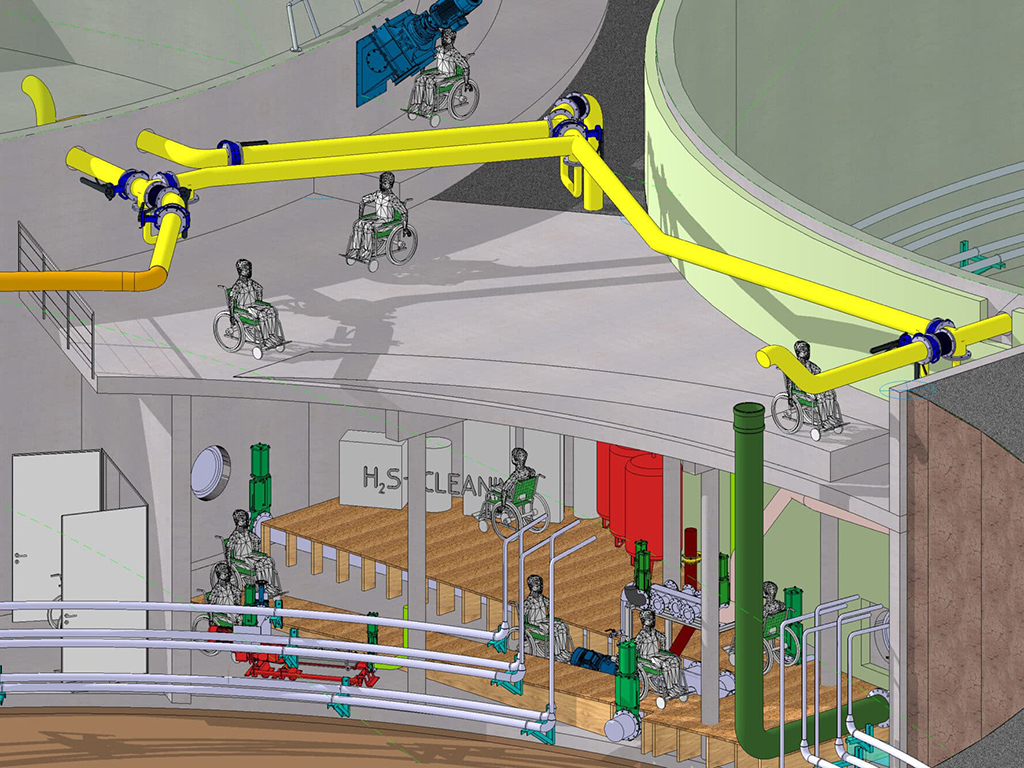

During the construction phase, starting with the consultation and the first sketch, up to the finished work planning: Our team is always at your side and supports you up to the approval. The design of the planning should be as uncomplicated and cost-effective as possible for you. Therefore, all steps up to the signature/verification of the person authorized to submit building documents and the completion of the building files for all offices are carried out in our company.

Hochreiter’s – farm biogas plant from 50kW – 150kW

We plan the biogas plant that suits your business and calculate honestly how much money is in your slurry, together with you!

Facts

Build a second source of business to stand on with your own farm biogas plant.

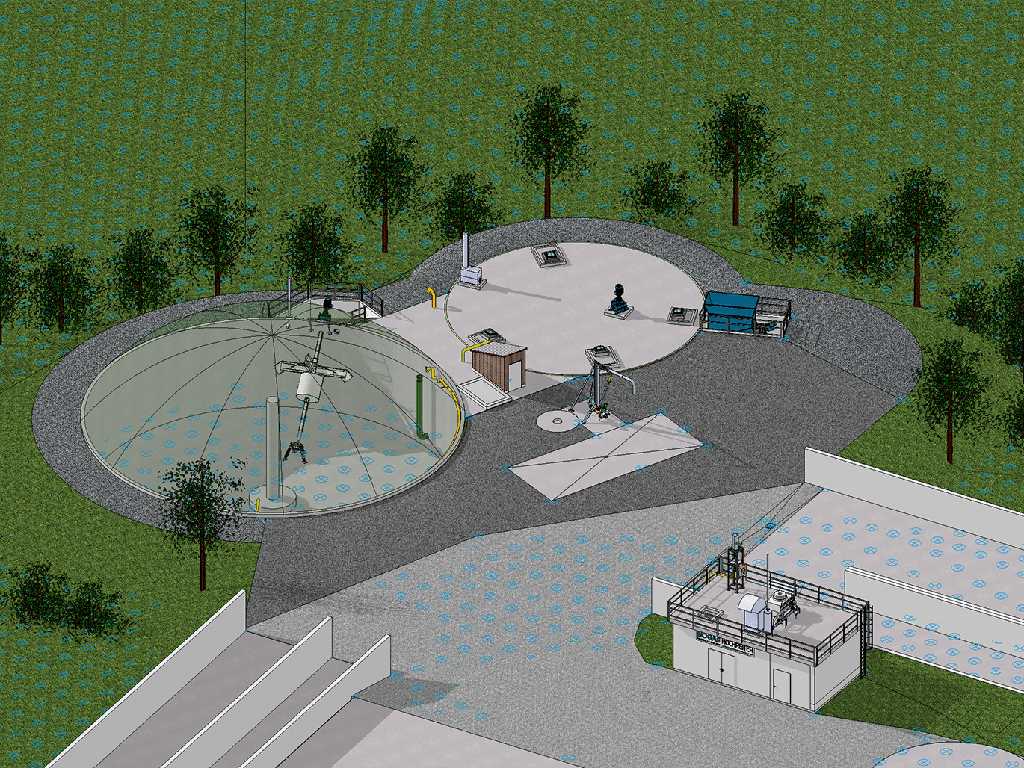

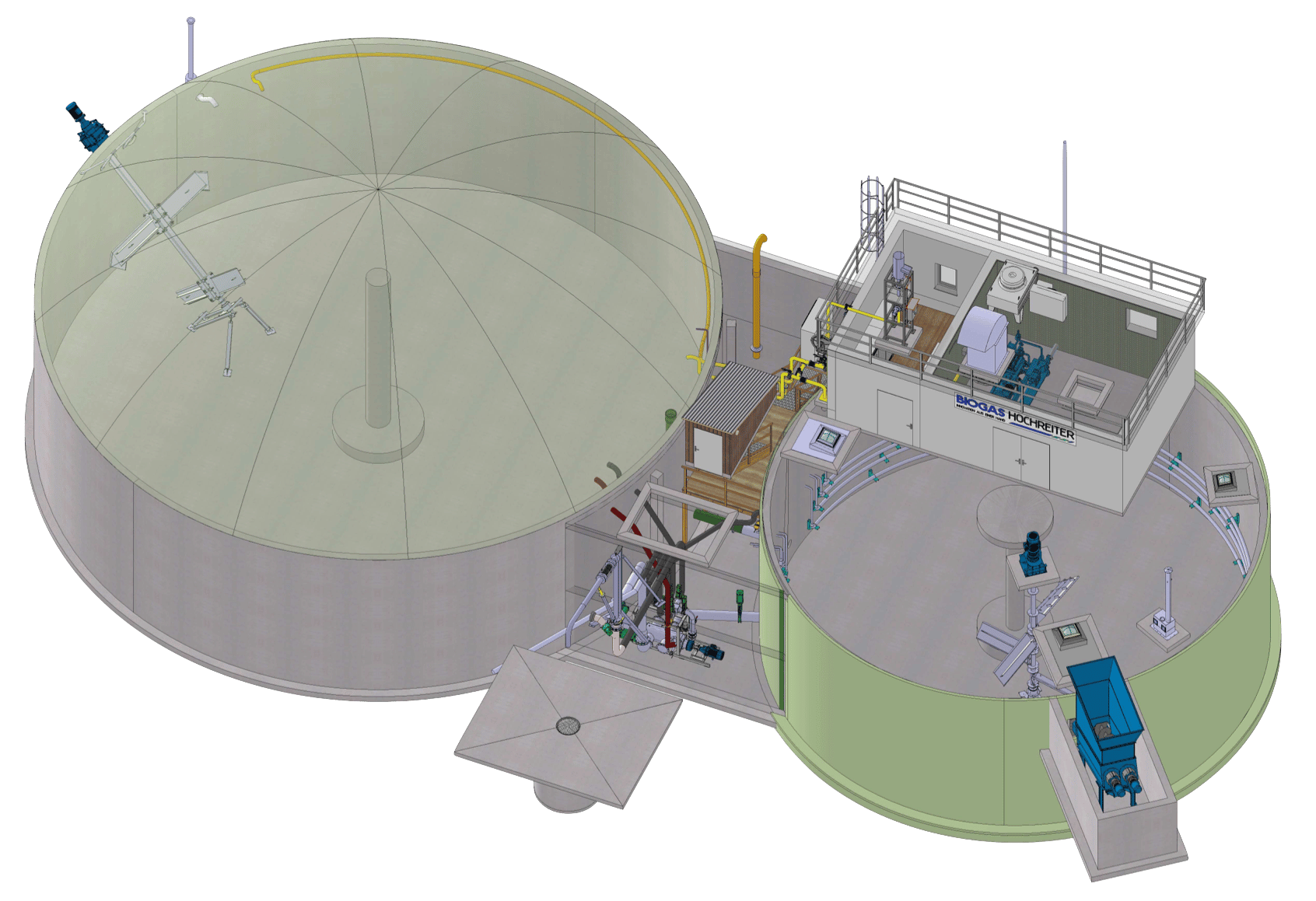

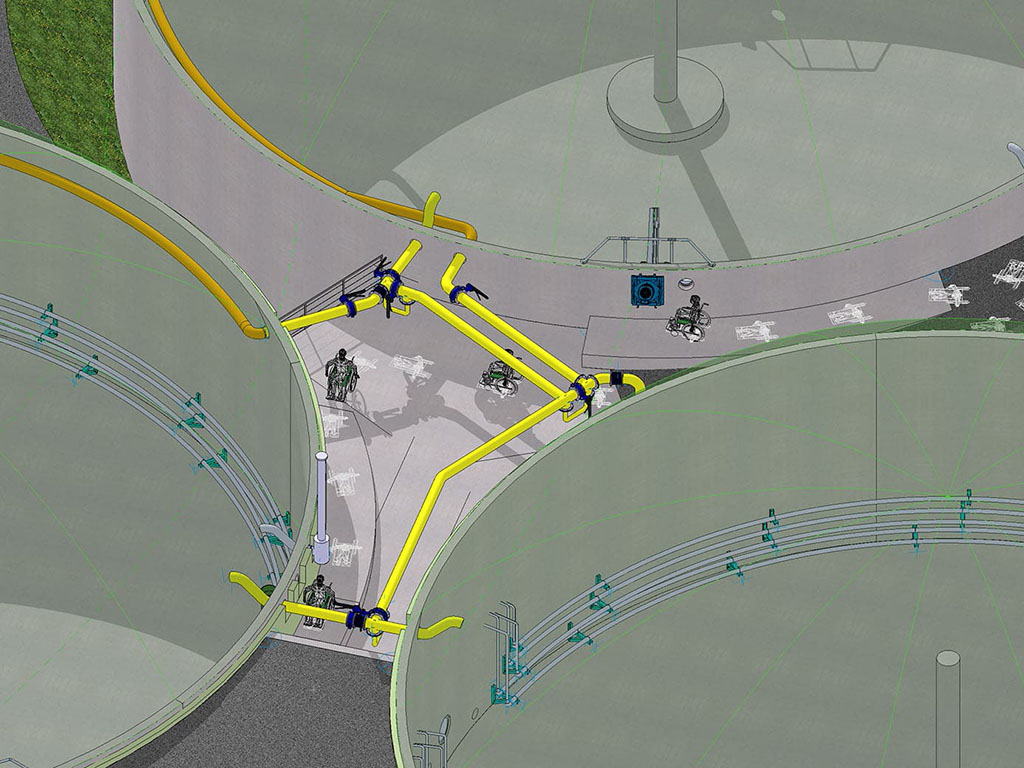

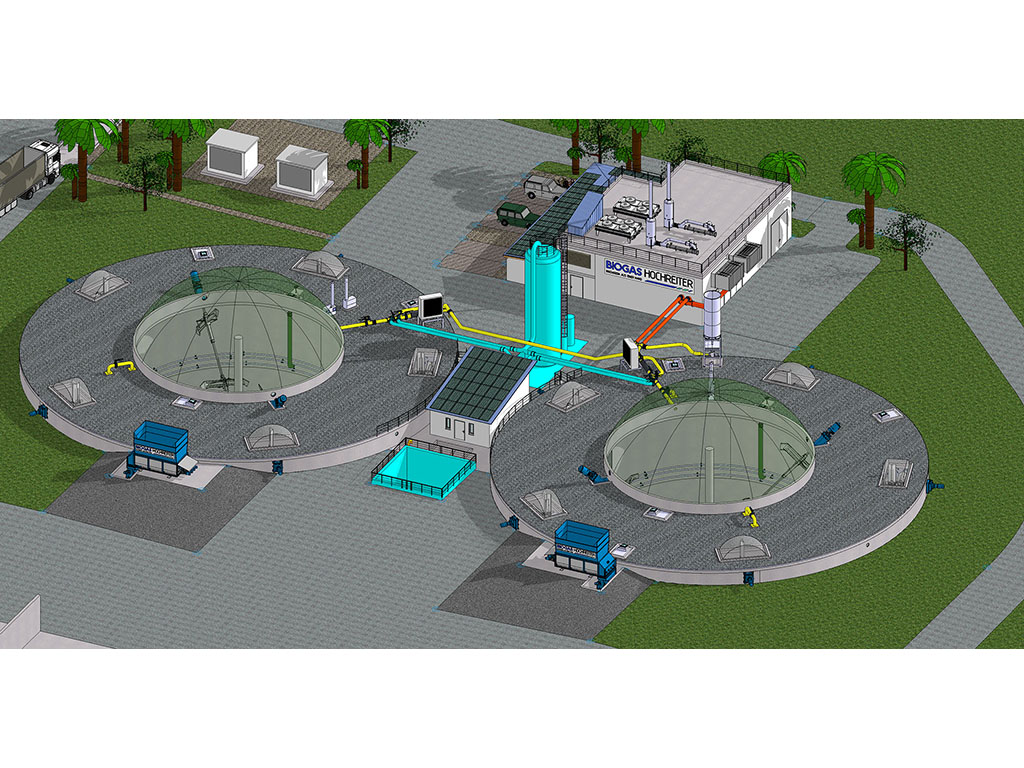

Information on the individual components of a Hochreiter – Farm Biogas Plant can be found in the graphic below.

Hochreiter’s – single tank plant

Hochreiter’s – PLANT SYSTEMS from 150kW

As a pioneer in the industry, operator and owner of our own biogas plants, we have a lot of experience in the sector. This experience benefits customers in design and construction, and in achieving the highest level of cost-effectiveness.

We adapt your future plant to your local conditions and wishes,

so that the plant runs uncomplicatedly, smoothly and, of course, economically.

That is why we have developed various concepts.

THIS IS WHAT SETS HOCHREITER PLANTS APART

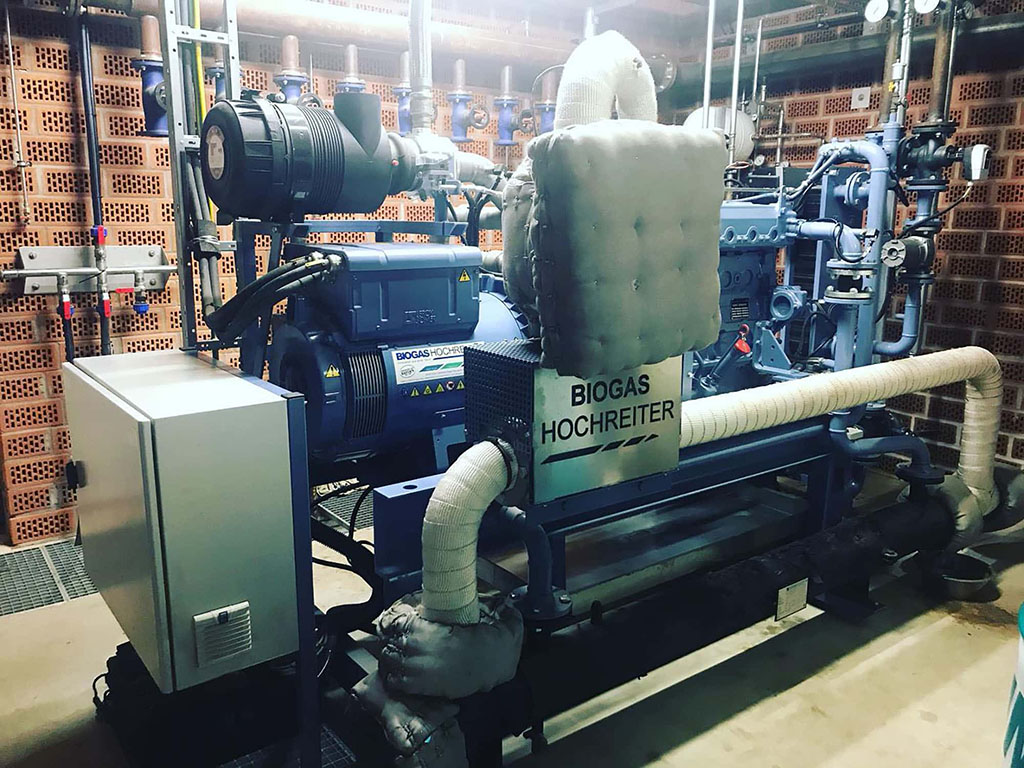

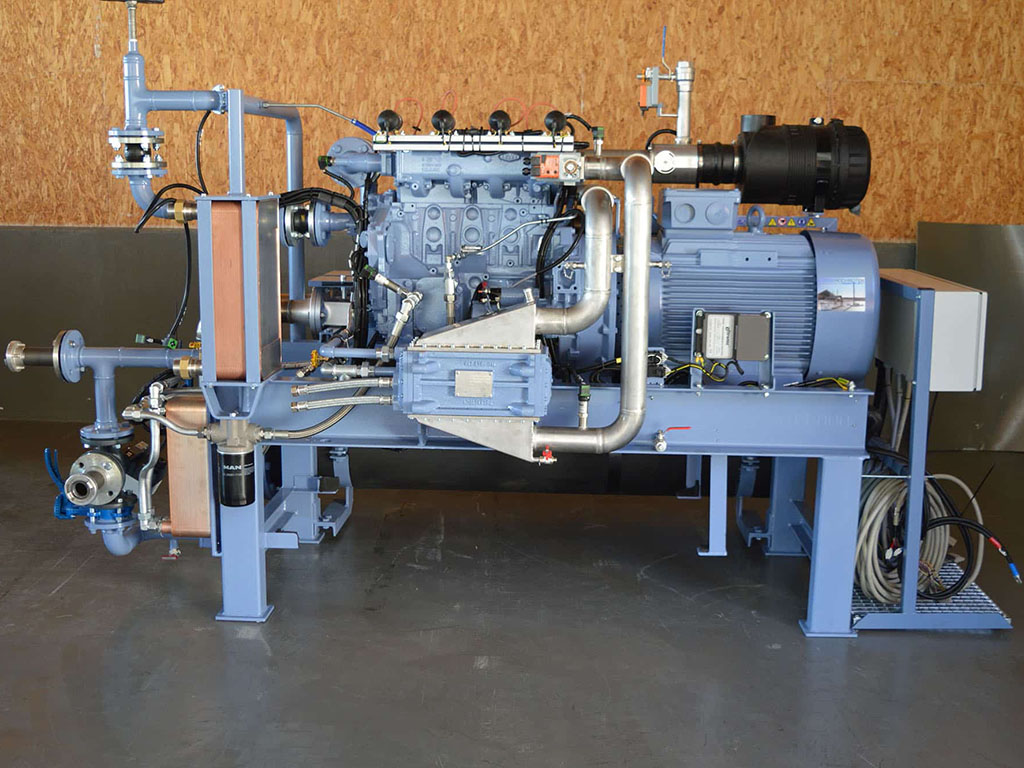

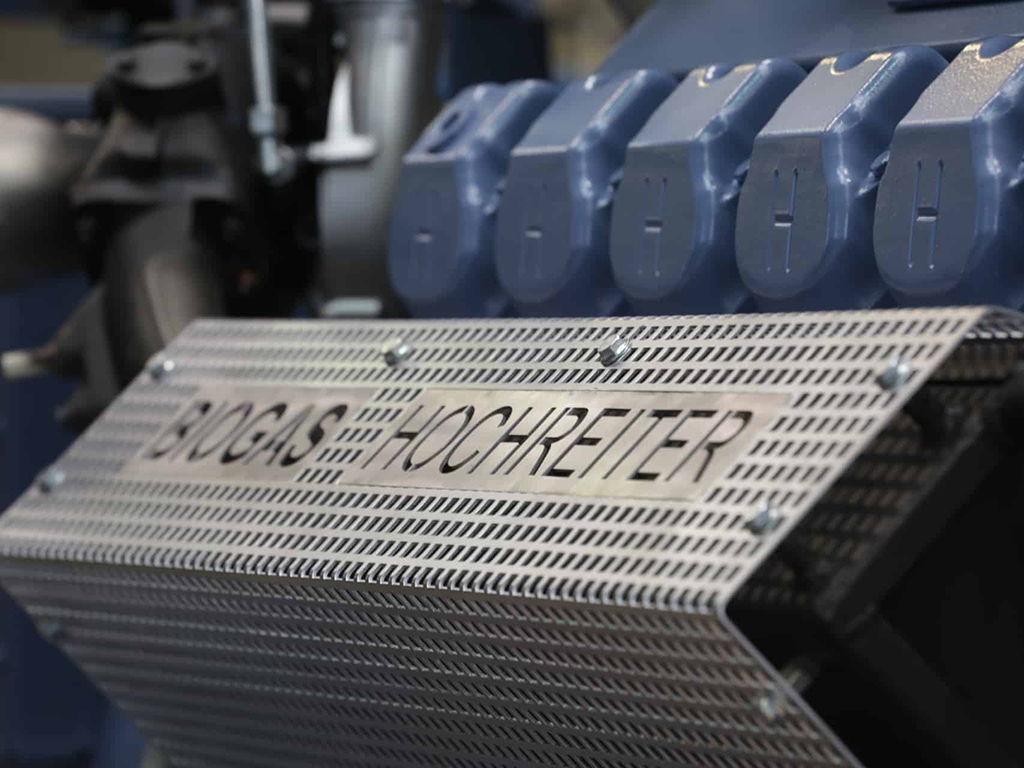

Hochreiter CHP’s

| Motor | Cubic capacity | Max. electr. Power | Therm. Power |

|---|---|---|---|

| HOMWM R6 | 6.24 liters | 75kW | 96kW |

| HOMAN TE34 | 4.58 liters | 85kW | 101kW |

| HOMAN TE36 | 6.87 liters | 110kW | 126kW |

| HOMAN LE36 | 6.87 liters | 100kW | 124kW |

| HOMAN TE76 | 12.82 liters | 150kW | 178kW |

| HOMAN LE76 | 12.82 liters | 200kW | 224kW |

| HODEUTZ V6 | 11.9 liters | 220kW | 273kW |

| HODEUTZ V8 | 15.9 liters | 310kW | 410kW |

| HOTEDOM | 11,95 liters | 210kW | 235kW |

| HOMAN H3076 | 12.3 liters | 190kW | 220kW |

| HOMAN H130 | 22.56 liters | 420kW | 484kW |

| HOMAN LE62 | 25.8 liters | 530kW | 588kW |

FLEXIBILIZATION

Biogas Flexibilization, more revenue, little effort in everyday life

A lot of new specifications and requirements have to be taken into account, in order to achieve more revenue for less effort on a day-to-day basis. Numerous questions arise for the plant operator.

Questions & Answers

We advise you in detail on questions concerning direct marketing, grid compatibility assessment and grid connection extension, transformer stations, environmental assessment for flexible operation, plant certificate, noise assessment, water law, acceptance in accordance with §29a BimSchG.

BIOMETHANE / LNG

Available quickly and at any time, versatile in use, resource-saving in production

Facts

Biogas consists mainly of 50-60% methane, the remaining components are CO2 and a small amount of trace gases. The latter are considered impurities and must be separated from the other components before being fed into the natural gas network.

The separation of biogas to high quality biomethane can be done with different methods.

The most common methods are membrane technology or PSA (pressure swing adsorption).

Membrane technology is used to compress the biogas and then filter the methane using modern separation modules. Here, several membrane pipes are usually used at the same time. This process is relatively simple and now technically very well developed, which ensures reliable operation.

In pressure swing adsorption, the biogas undergoes a pressure increase as the first step. Subsequently, the carbon dioxide molecules are adsorbed in special columns by strong and rapid pressure changes. This process is run a few times in several columns, and in the process the biomethane is extracted from the raw biogas.

CO2 is also produced during the production of biomethane. This can be used in greenhouses, chemical plants and for beverage and food production.